Your Quote

It all started with a TR6

… and a few expensive problems.

So instead of paying to get them fixed, John Skinner set about acquiring knowledge to repair the car himself. Through buying, selling and dismantling many Triumphs, John not only found himself with the parts he needed for his own repairs, but also a network of contacts and the beginnings of a small business in trading spares.

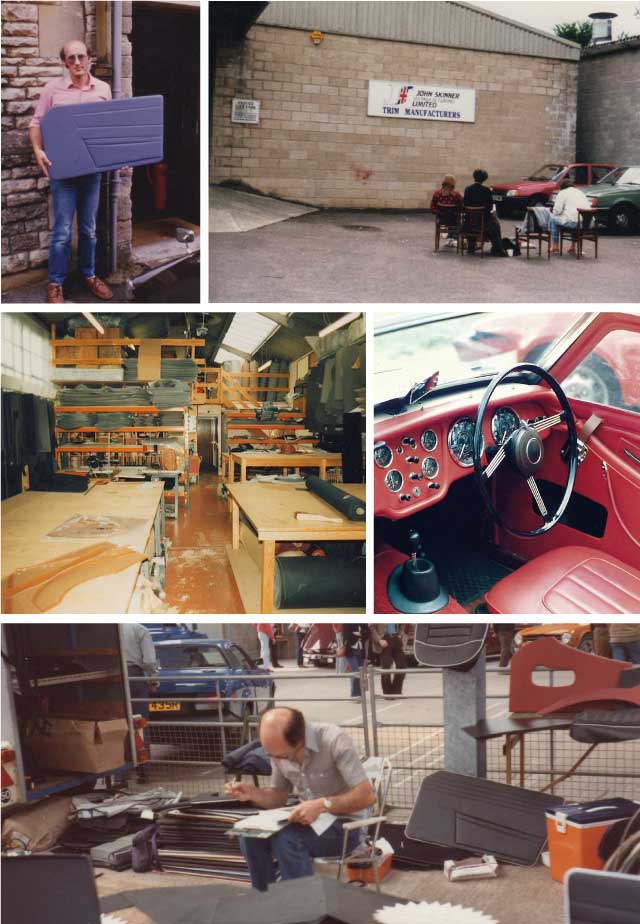

Spotting an opportunity for TR4/TR6 trim re-manufacture, John invested in the tooling required for trim panel production. His products were well received by many UK-based parts suppliers and by 1980 his hobby had developed into a small business that showed enough potential for growth to allow him to leave his full-time job.

As the business grew, so did the premises. When John’s home garage became too small, he relocated the workshop to a factory unit in Cirencester. From here, the product offering broadened to include trim for Jaguar XK, E-Type and MK2 to XJ-S Saloons. Austin Healey trim soon followed.

Over the years, John Skinner (Manufacturing) Ltd has quietly built an outstanding international reputation for quality interior trim and welcomes customers from all over the world; from the UK to Australia.

Our Team

… and tea, is what makes us who we are.

Our small but incredibly skilled team of machinists, trimmers and office staff are committed to delivering interior trim kits of distinction.

With the exception of some off-the-shelf parts, all of our products originate from our factory in Cheltenham and have been trimmed, sewn, packed and shipped by our dedicated team.

With some staff members having been with us for the best part of a decade, we know that our production is in knowledgable hands.

Truly a family business

… now in its second generation.

Founded through John’s passion and extensive technical knowledge of British classic cars, John Skinner (Manufacturing) Ltd has been shaped into the business it is today with the support of his family. John’s wife Judy and his children Joanna & Jonathon have all been a part of the company’s journey.

Today, John Skinner (Manufacturing) Ltd is based in the town of Cheltenham and is managed by John’s son, Jonathon and his wife, Lucy. Under Jonathon’s leadership, the business has embraced new cutting technologies, modernised its processes and moved into the ‘digital age’ all the while remaining true to the company values that his father established. And although now retired, John remains on-hand to offer technical knowledge and advice.

We proudly remain a family run business and we know our customers appreciate connecting with us directly.

Two generations of passion, skill and hard work have brought us to where we are today; a world leader in quality interior trim and upholstery manufacture.

We’ve come a long way from John’s garage.